Sensors

You can use a sensor to test your PLC. When a load passes a sensor, the sensor sends a signal to the PLC. You can program your PLC to react in different ways when a sensor sends a signal.

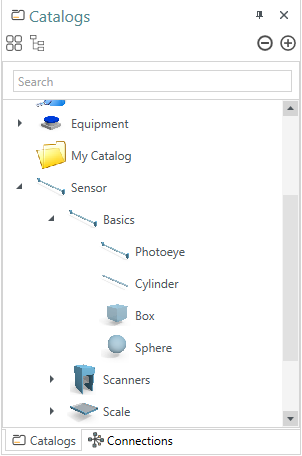

In the Experior catalog window you can find the sensors catalog. From there you can choose between several different sensors. The basics tab holds the Photoeye, Cylinder, Box and Square sensors:

These sensors offers the most basic functionality; to send a message to the PLC when a load passes them. The Photoeye sensor is special in the regard that it will adapt its size to fit your conveyor, while the other sensors come in a default size. However, you can adjust the size of all the sensors in their properties window. To install a sensor simply click it and place it over the conveyor you wish to install it on.

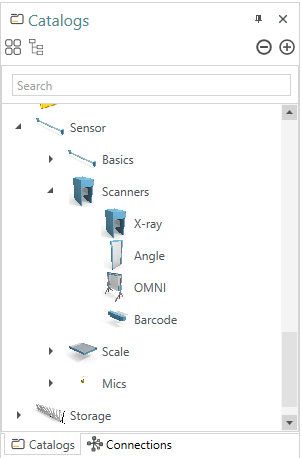

The scanners tab holds a few sensors with different functionalities:

The X-ray sensor can be set up to randomly flag some of the loads which passes it. You can choose how large a percentage will be flagged in the properties window of the sensor under screening>percentage

The Angle sensor registers at which angle the load hits it, and sends the information to the PLC.

The OMNI sensor and the barcode sensor has the same functionality, they only differ in size and look. Both will register when a load passes them and then scan the barcode related to that load and send this information to the PLC in the form of text. You can set the barcode for a load in the loads property window under Identification

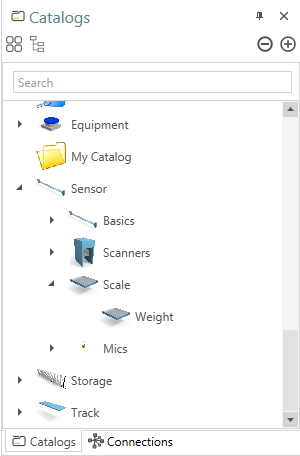

Under the scale tab you will find the weight sensor:

When a load hits the weight sensor, it will register the weight of the load and send the information to the PLC. It is possible to use different data types depending on your need but as default, the weight is measured in grams.

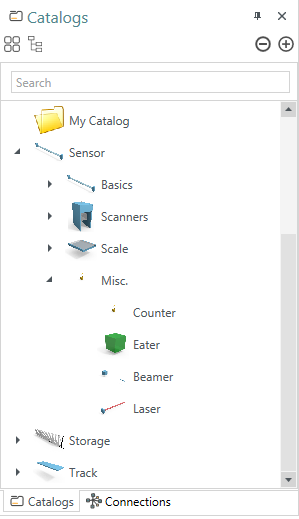

The last tab is the Misc. tab. Under this one you will find the Counter, Eater, Beamer and Laser.

The Counter has a little number above it that shows how many loads have passed it. In the properties window for the counter you can see how many loads has passed it in the last hour and the last minute.

The Eater eats the loads so they disappear from the scene. Read more bout the eater here.

The Beamer is made up of two connected parts. When a load hits one end of the Beamer, it is teleported to the other end of it. This allows the Beamer to work as a stand in for any part of the model, you have not yet finished. The load will simply skip the unfinished part when it hits one end of the Beamer and reemerge at the other end to continue its journey around your system.

The Laser sends out a laser beam. When a load hits the beam, the Laser figures out how far away the load is, and sends the information to the PLC in milimeters.

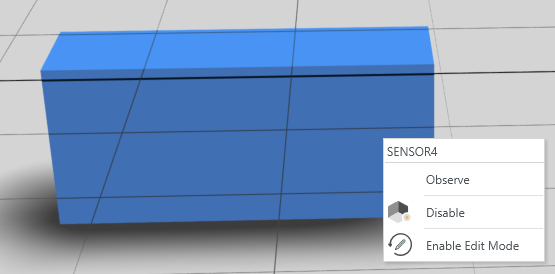

Some sensors can be observed. You mark a sensor for observation by right clicking it and choosing ‘observe’ in the menu:

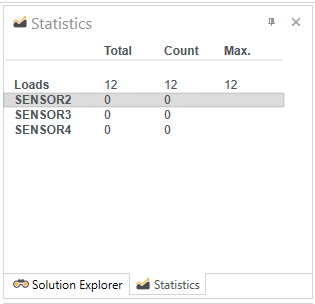

When you have activated the observation feature the sensor wills how up in your statistiscs window like this:

Now you can see, how many loads have passed the sensor. It is possible to rename the sensors in their properties window, so it becomes easier to tell them apart.

For more information see also Connecting an assembly to a PLC.